DRILLING AND MINING INSTALLATIONS

UBSH-101 DRILLING RIG

The INSTALLATION PROVIDES drilling of FRONT FACES IN WORKINGS with a cross-section of 2.5-2, 5M2, as well AS drilling HOLES in the ROOF AT a height of workings OF more than 3.5 M.

The UBSH – 101 drill shaft installation on a pneumatic-wheeled chassis is designed for drilling holes when driving horizontal mine workings in rocks with a strength coefficient of 8 – 20 according to GOST 21153.1 – 75. The installation provides drilling of front faces in workings with a cross-section of 2.5-2, 5M2, as well as drilling holes in the roof at a height of workings of more than 3.5 m.

According to the operating conditions in terms of the impact of climatic factors, the installation corresponds to the execution Of the placement category 5 according to GOST 15150-69.

The unit mechanizes all operations to guide the feeder with a puncher to the drilling points and provides self-propelled along horizontal mine workings, provided that compressed air is supplied to it.

TECHNICAL CHARACTERISTIC

Drilling zone, m, not less than the height from the reference surface-2.5

width-2.5

Number of drilling machines-1

Technical capacity of the installation, m / h, not less than-21

Drilling depth, m, not less than-2.2

Travel speed, km / h, at least-3.0

The greatest angle of the overcome rise, deg. - 12

Minimum internal turning radius of the installation, m-3.0

Overall dimensions of the installation in the transport position, m, no more:

width-1.1

height-1.4

length-6.5

Weight, t, no more than-5

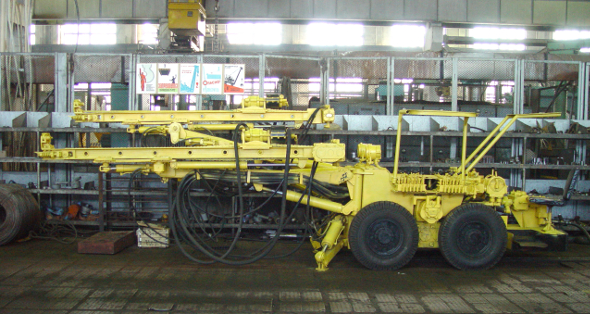

DRILLING INSTALLATION UBSH-207

THE INSTALLATION MECHANIZES LABOR-INTENSIVE OPERATIONS WHEN DRILLING HOLES, PARTIALLY AUTOMATES THE PROCESS AND ALLOWS YOU TO ADJUST THE DRILLING MODES IN A WIDE RANGE.

Drilling installation UBSH-207 is designed for drilling in a horizontal mine workings-section 6…13 m3 in rocks with strength coefficient f=8…20 on a scale M. M. Protodjakonova in mining and underground construction, tunneling and treatment plants in mining

The installation mechanizes labor-intensive operations when drilling holes, partially automates the process and allows you to adjust the drilling modes in a wide range

The unit has a convenient remote control for all drilling mechanisms and processes. The work platform located at the rear of the unit is equipped with a vibration protection device.

The installation consists of a running trolley, two swept hydraulically controlled manipulators with chain feeders, an oil station with a hydraulic system and a control panel. During operation in the face, the installation is supported by two hydraulic jacks.

The operation of the oil pump station, as well as the axial movement of the punches is carried out by pneumatic motors DAR-5B.

UBSH-207 drilling rig significantly improves the working conditions and safety of drilling operations in comparison with drilling with hand punches.

TECHNICAL CHARACTERISTIC

Productivity, m / h-33

Drilling zone, m-2, 5x3, 3

Diameter of drilling wells, mm-40 ... 65

Drill head feed stroke, m-2.5

Feed force, kgf-0 ... 700

Number of drill heads-2

Chassis-wheel and rail

Track - 600, 750, 900 mm

Travel speed, km / h-3.5

Specific air consumption, m3 / min-65.0

Compressed air pressure, MPa-0.5...0.7

Overall dimensions, m-1, 3x1, 5x6, 5

Weight, t, not more than-6,0

UBSH-221P DRILLING RIG

The INSTALLATION PROVIDES DRILLING FRONTAL FACES IN the WORKINGS SECTION 6...12 M2, as well AS DRILLING the FLANK (SIDE) of the HOLES at an ANGLE up TO 120 DEGREES FROM the LONGITUDINAL axis of the INSTALLATION AND DRILLING HOLES IN the ROOF AT the HEIGHT of WORKINGS of MORE than 3.5 M

The UBSH-221P drilling rig on a pneumatic-wheeled undercarriage is designed for drilling holes when passing horizontal mine workings in rocks with a strength coefficient of f=8…20 on the scale of M. M. Protodiakonov.

The installation provides drilling of front faces in workings with a cross-section of 6 … 12 m2, as well as drilling of flank (side) boreholes at an angle of up to 120 degrees from the longitudinal axis of the installation and drilling of boreholes into the roof at a height of workings of more than 3.5 m.

The unit is available in two versions: B106. 00. 000-01-for drilling holes in conventional mines with a positive temperature; B106. 00. 000-02 (Northern version) – for drilling holes when passing through permafrost placers underground.

The unit can be used for drilling holes when excavating various chambers up to 3.5 m high. The unit operates from compressed air with a pressure of 0.5 MPa (5 kgf / cm2), the air is supplied from the mine line by two

hoses. Compressed air provides the drive oil station hovering drill machine for drilling, flow drilling machines, downhole, drilling, drive carriage, drive lighting. The unit is controlled by pneumatic and hydraulic panels.

The use of on-Board truck drives provides high cross-country and maneuverability.

Autonomous lighting installed on the drilling rig provides the necessary illumination of the face and does not require the installation of an electric cable.

As a drilling tool, drilling rods of round section with a diameter of 32 mm or a hexagon section of 25 mm, with a shank for the drilling machine and drill bits with a diameter of 40…52 mm are used.

TECHNICAL CHARACTERISTIC

Productivity, m / h, not less:

- for rocks of medium hardness-33,

- on permafrost placers-42,

Drilling zone, not less than m-2, 5x3, 3

Feed stroke of the drill head, m-2,2

Travel speed, km / h, at least-3.0

The angle of elevation overcome by the installation in the transport position, deg. - 12

Maximum external turning radius, m-6,0

Minimum internal turning radius, m-1.5

Specific air consumption, m3 / min-25

Overall dimensions in transport position, m-1, 3x1,4x6, 5

Weight, t, no more than-6.5

DRILLING INSTALLATION UBSH-228

The INSTALLATION is USED IN the EXCAVATION SECTION 5-16 M2, UNFRAMED RAIL AND non-EXPLOSIVE GAS AND DUST

UBSH-228 is a drilling rig with a single hydraulic hammer and an electric drive designed for drilling holes in rocks with a strength coefficient of 8-20 on the Protodyakonov scale according to GOST 21153.1-75. The unit is used for sinking mine workings with a cross section of 5-16 m2, which are not equipped with rail tracks and are not explosive in gas and dust.

According to the operating conditions in terms of the impact of climatic factors, the drilling rig corresponds to the version V of category 5 of GOST 15150-69 (ambient temperature from+2O C to +26o C).

Installation on a pneumatic motor, has an electrohydraulic drive, so its use is recommended in combination with rock-loading or rock-delivery machines that have an electric drive. Mining operations that use a drilling rig must be equipped with an electric power supply with a voltage of 380 V and a power of at least 50 KW, air and water mains.

Application-underground mines of ferrous and non-ferrous metallurgy

TECHNICAL CHARACTERISTIC

Technical performance, m / h, not less:

with domestic hydroperforator-43

with imported hydropreparation - 54

The feed rate of gidrotartrata under load, m/min, no more - 1,5

Drilling zone (height from the reference plane x width), m, at least-4x4

Feed stroke (drilling depth), m-2.66

Chassis type-pneumatic

Travel speed, km / h, not less than 2.0

Overall dimensions in the transport position, mm, no more

width-1600

height (without protective visor) - 2100

height (with protective visor) - 2380

length-8300

Weight, kg, no more than-7500

HD-150 hydroperforator (manufactured by Boart longier, Austria)

Impact energy, j-224

Impact frequency in min-3000...3300

Impact power, kW-11.2

Rotation speed, rpm-190

Torque, Nm-315

Oil consumption, l / min

Udarnik-90

rotator-30

Oil pressure, kPa (kgf / cm2)

per drummer - 17.2 (170)

on rotator-14 (140)

Overall dimensions, mm

length-893

width-298

height-241

Weight, kg-150